Commissioning & Performance Testing Services

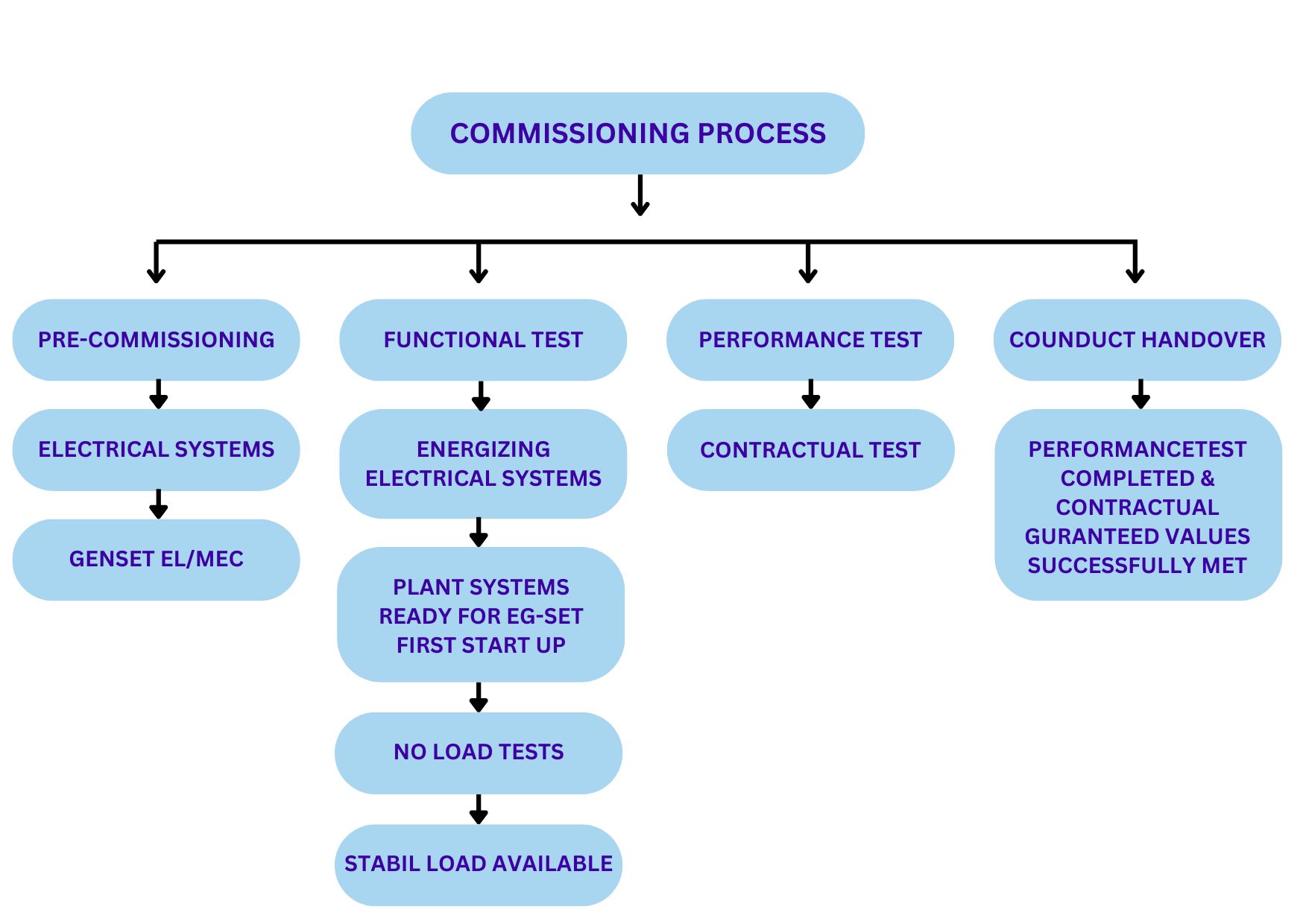

Fatima Engineering offers performance testing services to meet a wide range of customer needs, including pre-commissioning, commissioning of and new unit contractual acceptance testing + baseline testing for monitoring & trending purposes.

Our expertise covers reciprocating engines, gas turbine and steam turbine, and heat recovery steam generator and condenser equipment in simple cycle, combined cycle, industrial, fired-boiler Captive and IPP applications.

Fatima Engineering Performance testing services takes place at the customer’s site. All required personnel for successful completion of contracted performance testing will be provided onsite.

Features

- Acceptance & Performance tests available for all manufacturers supplied equipment as well as witness to performance tests as a third party.

- Extensive knowledge of and involvement with ASME performance test codes, providing vital insight into the requirements and expectations of a code test

- Testing may be customized to meet your budgetary and technical objectives

- Complete temporary precision instrumentation service capability

- Accurate test results and performance reconciliation

- Minimized impact of testing on commissioning schedules

- Commissioning protocols and commissioning of equipment

- Test protocols and testing of the equipment.

Operation and Maintenance Agreements

The Complete Operation & Maintenance Agreements or Asset management is all about managing risk. Signing an Operation and Maintenance (O&M) agreement means outsourcing risks to us. In return our customers receive performance and cost guarantees. In other words, We ensures peace of mind.

A power plant owner signing an agreement transfers the risk by receiving a guarantee of plant performance, efficiency and availability together with reliable estimates of future expenditure. A fixed price O&M agreement with We enables owners to predict their plant’s lifecycle costs accurately. To date our customers have trusted us to manage more three (3) installations under O&M agreement.

There are different benefits that a power plant owner looks for when entering a long-term service agreement.

- First of all a reliable partner is needed that remains throughout the installation’s entire lifecycle.

- Secondly, price predictability – Signing an agreement ensures that there will be a fixed price on the maintenance costs for the agreement period.

- Last but not least, there will be specific guarantees for plant availability, performance and economy.

Your installation is in good hands

What would an agreement be without the skilled people performing the actual work? , Power Master is a company with a strong service network, which means that we are able to employ skilled people to execute the O&M agreement. In terms of customer relations it is important that the personnel are skilled and competent to build trust.

We ensure that our own pool of experts has the right skills and qualifications for the job at hand. Our people receive training on a regular basis, either on site by our own training personnel or by working at some other plant that we operate to watch, learn and gain experience. We encourage plant rotation, which keeps people alert and motivated. For bigger maintenance overhauls we engage our Field Service organization.

A long-term O&M agreement can produce economic benefits

Although power plant owners may very well be able to operate their plants independently, they would, however, want to get the most out of the plant in terms of performance and efficiency. We can provide calculations to show the economic benefit of signing a long-term service agreement. Furthermore, customers do not have to put time and effort into trying to find suitable spare parts. With an agreement all is taken care of for several years to come, so operators can fully focus on their business.

Through an O&M agreement we maintain the plant’s fuel economy, which has a direct positive impact on your profits and enhances a sustainable business operation through lower emissions. We also guarantee the performance and efficiency of the plant according to the signed contract. Nowadays it is also usually a requirement from external investors that a reputable Operation & Maintenance Company should be involved.

When signing an asset management agreement, operators know exactly what their maintenance expenses are for the coming years.

Service Agreements

A service agreement signed with Fatima Engineering is an ideal way of keeping your installation productive and profitable. For a power plant owner an agreement assures that while you focus on your core business, we make sure your investment is highly efficient and productive throughout its lifetime.

A power plant owner will often have technically skilled people who are very capable of operating the plant. We can add to that value chain through an agreement that includes financial predictability, in-house and back office expertise, access to technical experts, having the latest information on product development and technical upgrades, and last but not least a guarantee that only OEM spare parts will be used.

We offer four types of standardized agreements ranging from

- Supply Agreements

- Technical Management

- Maintenance Agreement

- Complete O&M – Asset Management Agreement.

In all cases, we listen carefully to our customers’ needs and hence tailor-make an agreement to fit any installation and business situation.

There are many good reasons for signing a service agreement with us. Among them the top two benefits:

- An extended lifecycle for your plant with a lifecycle cost guarantee

- Performance guarantees. Through skilled people and latest technology we assure high availability and performance, which mean less downtime

An annual maintenance plan is always included in an agreement. The plan is made according to your production cycle, meaning that maintenance downtime is scheduled to cause the least possible disruption. Another aspect to this is the dynamic maintenance plan, which means that we check the condition of the components, and make suggestions to the plant owner to either bring forward or postpone the maintenance and combine it with other scheduled maintenance to reduce the downtime.

The basic idea behind a service agreement with Fatima Engineering is long-term cooperation where both parties work towards a shared goal: the client company’s continued productiveness – and profitability. An agreement ensures and optimizes performance, with guarantees that a particular level of performance will be reached and maintained. The productive lifetime of the plant and your return on investment is maximized, with lifecycle cost guarantees.